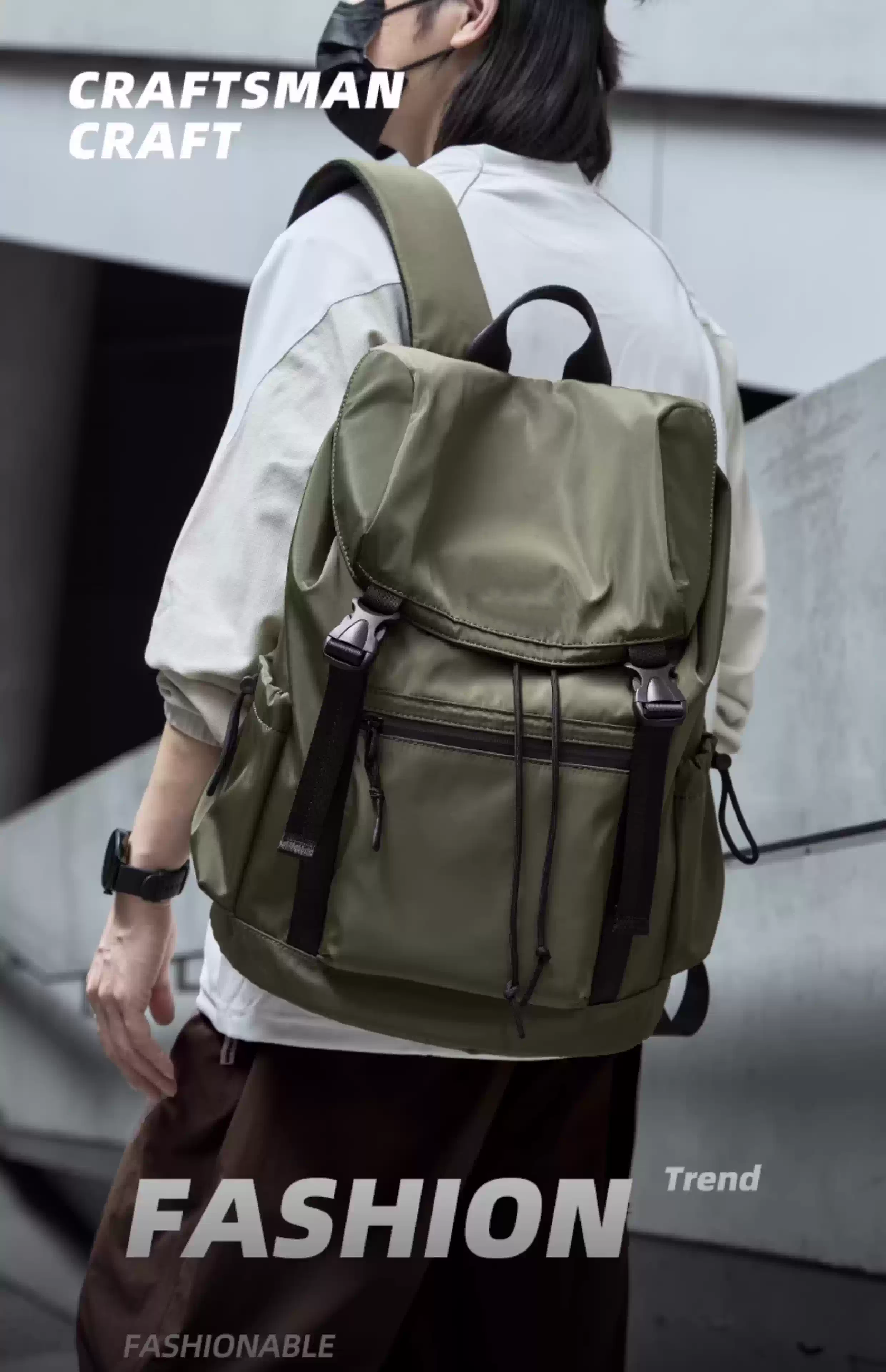

winter skitrips bag factory

The winter skitrips bag factory stands as a state-of-the-art manufacturing facility dedicated to producing high-quality bags and equipment storage solutions for winter sports enthusiasts. This cutting-edge facility combines advanced manufacturing processes with innovative design principles to create durable, weather-resistant bags specifically engineered for ski equipment. The factory utilizes automated production lines equipped with precision cutting tools and reinforced stitching machines to ensure consistent quality across all products. Each production station incorporates quality control checkpoints that monitor material integrity, seam strength, and waterproofing effectiveness. The facility's research and development department continuously works on incorporating new materials and technologies, such as RFID tracking capabilities and smart storage solutions, to enhance product functionality. The factory's production system is designed to accommodate both large-scale orders and customized requests, featuring flexible manufacturing cells that can be quickly reconfigured to meet varying product specifications. Environmental sustainability is integrated into the manufacturing process through energy-efficient machinery and recycled material usage, reflecting the factory's commitment to eco-friendly practices.